Description

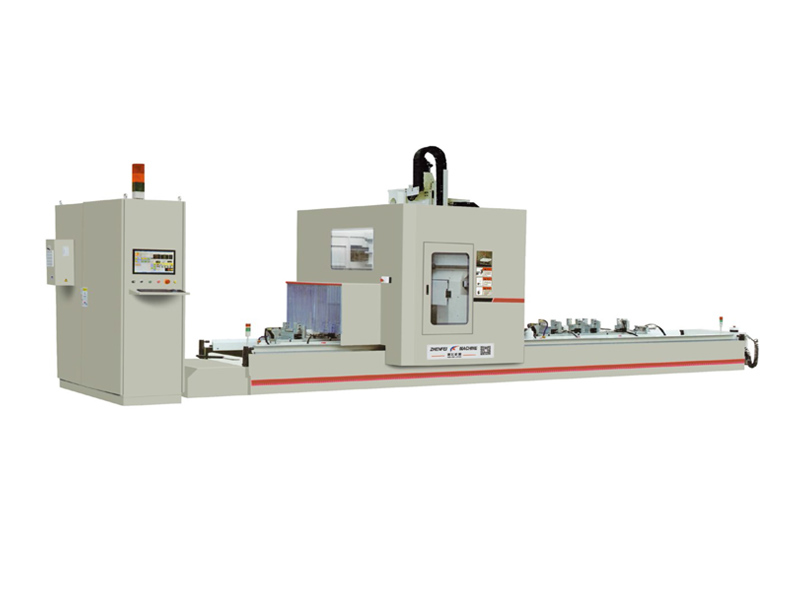

This machine can achieve one-time clamping of raw materials, and according to processing needs, it can complete multiple processes such as cutting, milling end tenons, milling lock hole slots, water flow slots, air pressure balance holes, installation holes, etc., truly realizing a "one person door and window processing system" and meeting customers' personalized customization of doors and windows.

Suitable for various types of aluminum, copper PVC、 Processing of complex parts such as industrial profiles.

Adopting a dynamic beam and column gantry frame structure, the operation is smoother and the machining rigidity of the machine tool is improved.

Ø We use high-quality imported servo motors, ball screws, linear guide pairs, and bearings to ensure that the equipment has high machining accuracy, stability, and reliability. The feed movement is pre stretched to ensure stable machining accuracy.

This machine adopts imported five axis milling head, which can complete machining at any angle on all surfaces except for the bottom surface. Automatic tool changing with row type, optional vertical disc type tool magazine.

The central centralized automatic feed lubrication method with quantitative timing ensures the stability of machine tool accuracy.

Using a pneumatic clamping workbench to improve loading and unloading speed. Optional T-shaped workbench.

Adopting safety protection functions to ensure safety.

中文

中文 English

English