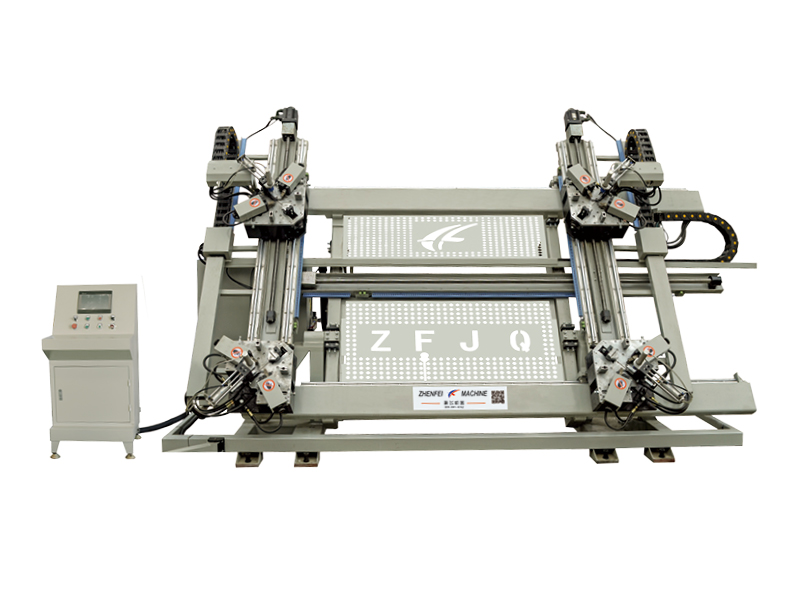

Description

Adopting a high-quality CNC system that balances speed and accuracy.

The relative position between the corner oil cylinder and the worktable can be fixed through the pin hole connection method, without the need to adjust the height and left and right of the corner cutter. Customized corner cutters can be made according to the profile to meet the customer's corner requirements.

All four machine heads are equipped with extendable and large stroke auxiliary external positioning devices, which facilitate reliable fan material assembly.

The ultra long internal positioning oil cylinder stroke makes it easier to install a dedicated backing plate for processing the fan material window.

One time framing can control the seams and flatness between profiles, making the quality of framing predictable.

The hydraulic system can automatically switch between high and low pressure during the corner forming process, ensuring the accuracy of corner forming.

中文

中文 English

English