Description

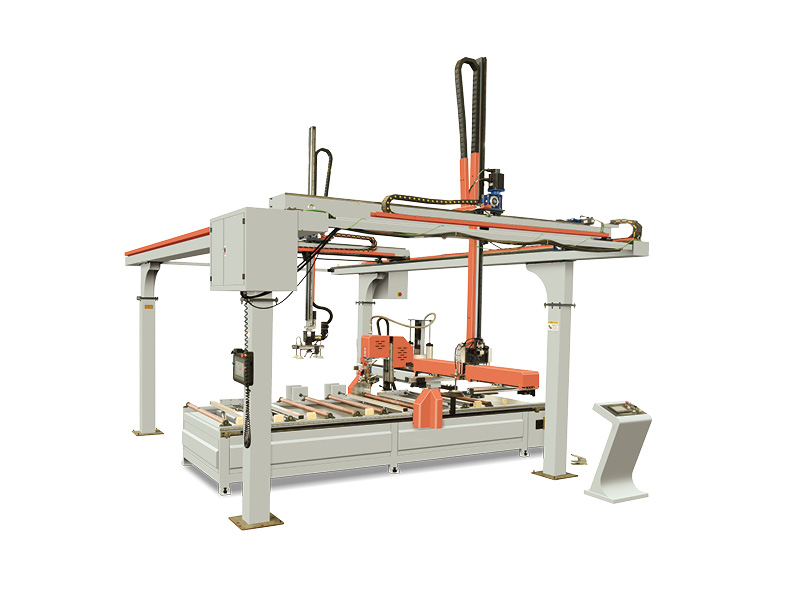

An automatic flipping, automatic loading and unloading, and automatic gluing production line.

Mainly composed of a gantry section and an automatic gluing machine.

The gantry section mainly consists of an automatic flipping part, a window sash buffer rack, a gantry gripper part, and an electrical control part.

The automatic gluing part is composed of an automatic gluing machine.

This device is used for sealing and gluing doors and windows. It can automatically sense the size and height of the glass, apply glue automatically, and can be operated by ordinary workers without the need for a glue master.

Apply glue layer by layer, saving the trouble of moving the fan twice, solving the problem of glue not drying out and fan deformation during moving. After gluing, pull the entire stack away.

Multiple workstations can be used for cyclic gluing as needed to improve efficiency, with 500-800 units glued per shift.

The equipment is evenly and beautifully glued, with a 45 degree corner and good sealing performance.

Adopting single component silicone sealant (25 kg/barrel, 20 liters), this adhesive has good elasticity and high strength, making it an ideal choice to replace traditional door and window rubber strips. The price of barrel adhesive is about 5% lower than that of packaged adhesive.

For built-in louvers, it is possible to apply glue on three sides.

中文

中文 English

English